It is no wonder that company

management looks at maintenance with a jaded perspective. Many of them still think of maintenance as a

necessary evil that is just a cost of doing business.

I am referring to failed

reliability improvement initiatives. Research conducted at Reliabilityweb.com

shows that approximately 85% of these improvement initiatives fail to create

sustainable business gain.

Some improvement efforts do

makes things better for a little while but then they return to the previous

state or worse. We call this

“bureaucratic elasticity”. Like a rubber

band being stretched outward, it only remains in that position while it is

being held. Once released it returns to

its original position.

Maintenance leaders often

follow the “silver bullet” approach because they met some “expert” who sure

seemed credible as they explained the “only way” to make improvements. (The “only way” also happened to be the

method that this consultant knew about).

If your maintenance consultant is telling you about the “one way” to

make the journey to high-performance reliability, run away fast. There is no such thing.

Things like

Reliability-centered maintenance (RCM), Computerized Maintenance Management

Systems (CMMS), Predictive Maintenance (PdM) or Maintenance planning and

scheduling are all fantastic improvement strategies and tools, however the

power for change is not resident in the tools themselves.

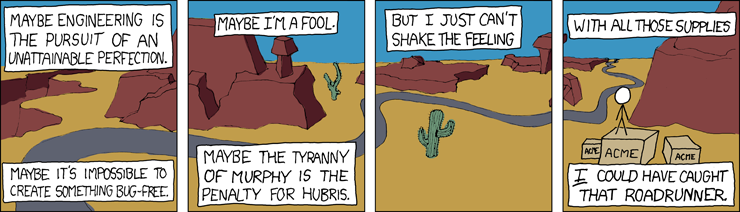

Do you recall Wile E. Coyote,

the Warner Brothers cartoon character that was always trying to capture and eat

the Roadrunner?

I do not know where he got

his budget but his wily mind was able to engineer very elaborate plans using a

wide variety of strategies, tools and technologies (all available from Acme

Manufacturing), however none of them ever delivered a meal to his plate.

Of course as maintenance

reliability leaders, we need to use any strategy, technology and tool that will

help us reach our performance goals, but the lessons of the last 30 years have

demonstrated that creating a sustainable high-performance reliability level is

not a by-the-book journey.

Since 2006, Uptime Magazine

has hosted the Best Maintenance Reliability Program Award or Uptime Awards for

short. Over the years we have found 7

traits that each of these winning high-performance programs share:

1) Each program developed

maintenance and condition monitoring tasks based on criticality ranking and

failure modes and effects analysis. In other words they understood how their

machines failed and how important they were to company goals. They directed maintenance activity to detect

or prevent potential failures on the right machines at the right time.

2) Each program had earned a

high level of active corporate support and respect by starting small, assessing

the result, improving, then expanding.

Company leadership did not simply endorse the reliability improvement

program; they understood it and actively guided it so it could survive competing

initiatives and temporary loss of faith.

3) Each program excelled in

communicating up the chain, down the chain and across the chain. All

stakeholders and interested parties had a high awareness about the

benefits of the program.

4)

Each program included short and long-term training and certification for team

members that were far higher than what we typically find in lower performance

companies

5)

Each program included passionate and energetic people who were highly motivated

to perform at high levels. Many of these people had no management

authority however they were clearly leaders who possessed initiative.

6)

These programs reported gains in safety, productivity and reliability on a

regular basis to justify and sustain the reliability improvement program.

7)

Each program subjected itself to annual assessment in order to identify current

gaps, and then created follow-up plans to close those gaps. They expect

to continually improve with no end in sight. If you have been through an

honest assessment, you know how painful it can be.

Are you still chasing the

roadrunner?

Here are some resources that

might be useful for your journey

What are your thoughts about

creating a sustainable high-performance reliability program?

No comments:

Post a Comment